Silicon Laboratory

HOME

Equipment Status Silicon Laboratory

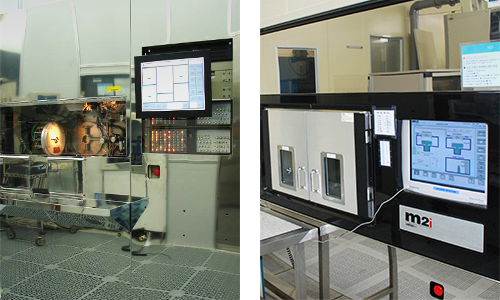

I-Line Stepper

Maker(model)

Application

- Resolution : 350nm

- Alignment Accuracy : 70nm or better(LSA, FIA)

- Exposure Area : 22mm square

- Reduction Ratio : 1:5

- Numerical Aperture : 0.63

- Reticle : 6 inch

Substrate

- Silicon Wafer, 6 inch

- Quartz Wafer, 6 inch(@ i11D)

- Glass Wafer, 6 inch(@ i11D)

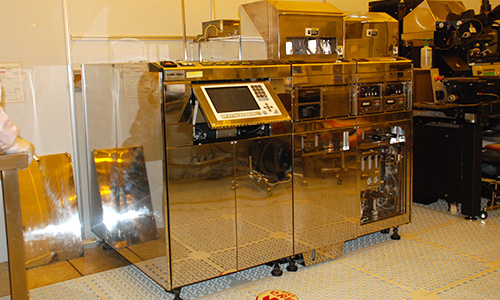

Track System

Maker(model)

- TEL(Mark-Vz), TSTI(Smart-cube)

Application

- Adhesion Treatment(HMDS) on Substrates

- Photo Resist Coating

- Development(TMAH) : Puddle&Spray

- Hot Plate Baking

Substrate

- Silicon Wafer, 6 inch

- Quartz Wafer, 6 inch(@TSTI)

- Glass Wafer, 6 inch(@TSTI)

Dry Etcher

Maker

Application

- Oxide Etch

- Nitride Etch

- Poly-Si Etch

- Metal Etch

- PR Strip

Substrate

- Silicon Wafer(6 inch, Piece)

- Quartz Wafer(6 inch, Piece)

- Glass Wafer(6 inch, Piece)

Wet Station

Maker

Application

- Standard Cleaning : H2SO4/H2O2 + 100:1 HF Cleaning

- SC1 Cleaning : NH4OH4/H2O2 + 100:1 HF Cleaning

- HF Cleaning : 50:1 BHF, 100:1 HF Cleaning

- DI Cleaning

- H3PO4 Etch : Nitride Strip @160℃

- Wet Etch : Oxide Etch, Metal Etch

- PR Strip : Acid PR Strip

Substrate

- Silicon Wafer(6 inch, Piece)

- Quartz Wafer(6 inch, Piece)

- Glass Wafer(6 inch, Piece)

LPCVD

Maker

- centrotherm(E1550HT), 5Tube

Application

- TEOS Oxide : 710℃, 250mTorr, TEOS 40sccm

- Nitride, Low Stress Nitride

- 770℃, 250mTorr, NH3 300sccm, DCS 50sccm

- 825℃, NH3/DCS 30/150sccm ~ 50MPa Stress

- Poly Si/Amorphous Poly Si

- 625℃, 200mTorr, SiH4 72/68sccm

- 530℃, 200mTorr, SiH4 72/68sccm

- LTO : 425℃, 160mTorr, SiH4 160sccm, O2 160sccm

- HTO : 850℃, 350mTorr, DCS 40sccm, N2O 160sccm

- SiON : 850℃, 200mTorr, NH3 20sccm, DCS 20sccm, N2O 80sccm

Substrate

- Silicon Wafer(6 inch, Piece Thickness : 1mm or less)

- Quartz Wafer(6 inch, Piece Thickness : 1mm or less)

- Glass Wafer(6 inch, Piece Thickness : 1mm or less)

PECVD

Maker

Application

- Oxide : 400℃, 3Torr, SiH4 60sccm, N2O 1200sccm

- Nitride : 400℃, 4.5Torr, SiH4/NH3/N2 185/75/1800sccm

- TEOS : 400℃, 5Torr, O2/He/TEOS 950/560/950sccm

- SACVD BPSG : 480℃, 200mTorr, O3 4000sccm, TEOS/TEB/TEPO 500/187/68mgm

- Oxynitride : 400℃, 4Torr, SiH4/N2O/N2 160/80/1000sccm

- Ge Oxide : 400℃, 3Torr, SiH4 80sccm, N2O 1200sccm, GeH4

Substrate

- Silicon Wafer(6 inch, Piece)

- Quartz Wafer(6 inch, Piece)

- Glass Wafer(6 inch, Piece)

Sputter

Maker

Application

- Al-1%Si : 200℃, 4.2KW

- TiW : 100℃, 3KW

- NiV, Cr, Mo : 100℃, 1.2KW, Variable Condition

- Ti, TiN : 400℃, 2.4KW(Ti), 7.2KW(TiN)

- AlN : 200℃, 1.9KW, N2/Ar 65/13sccm

- NbN : Room Temp. 2.4KW, N2/Ar 20/20sccm

- Pure Al, Al-1%Si : 200℃, 9.6KW

Substrate

- Silicon Wafer(6 inch, Piece)

- Quartz Wafer(6 inch, Piece)

- Glass Wafer(6 inch, Piece)

Furnace

Maker

Application

- Alloy : 400 ~ 460℃

- Wet/Dry Oxidation, Anneal, Drive-in

- 800 ~ 1250℃

- P-type Wafer Process

- Wet/Dry Oxidation, Anneal, Drive-in

- 800 ~ 1250℃

- N-type Wafer Process

- Dry Oxidation, Anneal : 800 ~ 1250℃

- POCl3 Doping : 800 ~ 900℃

Substrate

- Silicon Wafer(5 inch, 6 inch, Piece Thickness : 1mm or less)

- Quartz Wafer(5 inch, 6 inch, Piece Thickness : 1mm or less)

- Glass Wafer(5 inch, 6 inch, Piece Thickness : 1mm or less)

RTA

Maker

- Kornic System(Korona 600S)

Application

- RTA : Ar or N2 Ambient, 600 ~ 1100℃

Substrate

- Silicon Wafer(6 inch, Piece)

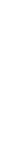

Ion Implant

Maker

Application

- Medium Current Ion Imp.

- BF2, B11, Ph Ion

- Max 180KeV

- Ion Dose : ~ 1E14

Substrate

- Silicon Wafer(6 inch, Piece)

Ion Implant

Maker

Application

- High Current Ion Imp.

- BF2, B11, Ph, As Ion

- Max 180KeV

- Ion Dose : ~ 1E16

- Max 18ea Wafer Loading

Substrate