ICT Trend

Vol.73

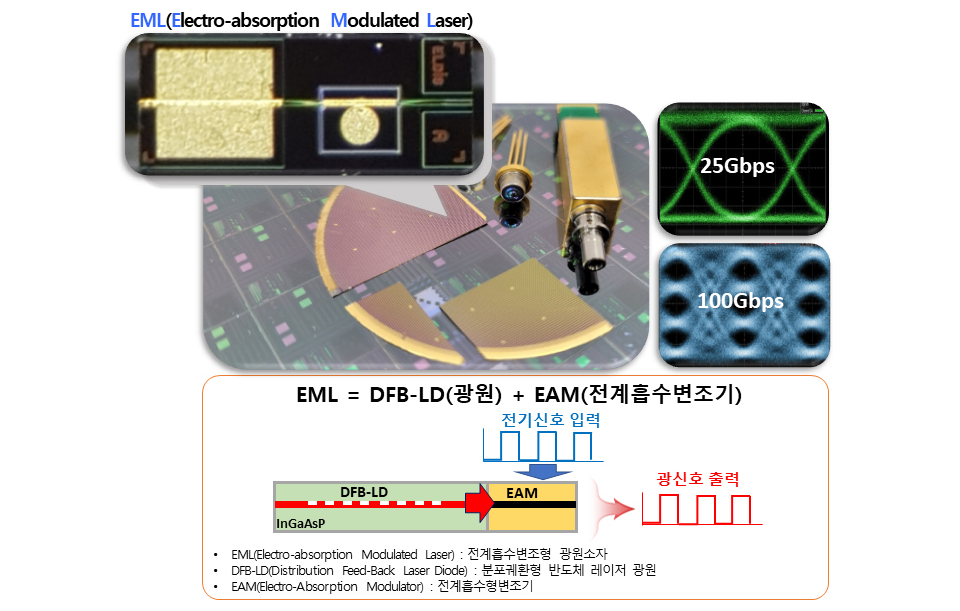

ETRI commercializes a light source device capable of transmitting 25 Gbps 30 km

- Localized 25 Gbps electro-absorption modulator-integrated laser with ELDIS Co., Ltd.

- Will expand 100 Gbps network market such as 5G mobile and data center network

Korean researchers and an SME have successfully commercialized a light source* capable of transmitting 25 billion bits per second over long distances for the first time in Korea.

Electronics and Telecommunications Research Institute(ETRI) announced that it has succeeded in commercializing an electro-absorption modulator-integrated laser(EML**) capable of transmitting data over 30 km at a speed of 25 Gbps with ELDIS Co., Ltd., a III-V semiconductor laser diode chip maker. Recently, the demand of high speed EML chips is rapidly growing according to the explosively increasing network traffic due to the wide spreading 5G mobile and AI driven services.

In order to accommodate large data traffic network equipments usually have been adopting a directly modulated laser(DML) modulated by applied current to turn it on and off. However, when it comes to higher speed and longer reach data transmission, DML had limitations in that due to physics of delayed current charging and discharging time which significantly reduced modulation speed, and deteriorated signal quality.

* Light source: An element that converts electrical signals into optical signals and is manufactured by a compound semiconductor process

** EML: Electro-absorption Modulated Laser, a compound semiconductor light source element that modulates optical signals using an electric field absorption method

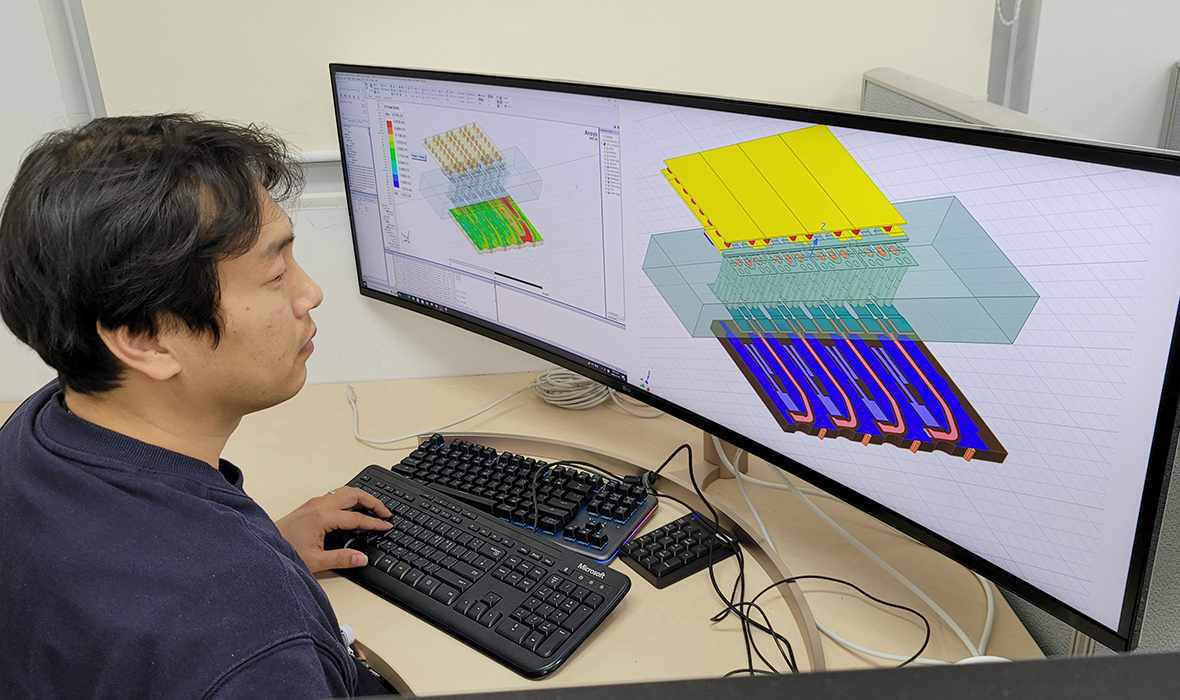

ETRI has developed an EML replacing a DML to address the higher speed and longer reach requirement. EML modulates the intensity of output light much faster than DML using electro-absorption modulator(EAM)* integrated at the end of its output part and absorbs light momentarily proportional to the applied voltage. This voltage modulation drastically enhanced the modulation speed compared with a DML’s current modulation of which modulation speed is limited due to the electric capacitance of a laser diode.

Currently, only a few companies around the world can supply EML to the market, which means it is very meaningful achievement to become a leading chip maker.

* EAM: Electro-Absorption Modulator, An element that modulates an optical signal by absorbing a light source proportional to the strength of the applied voltage

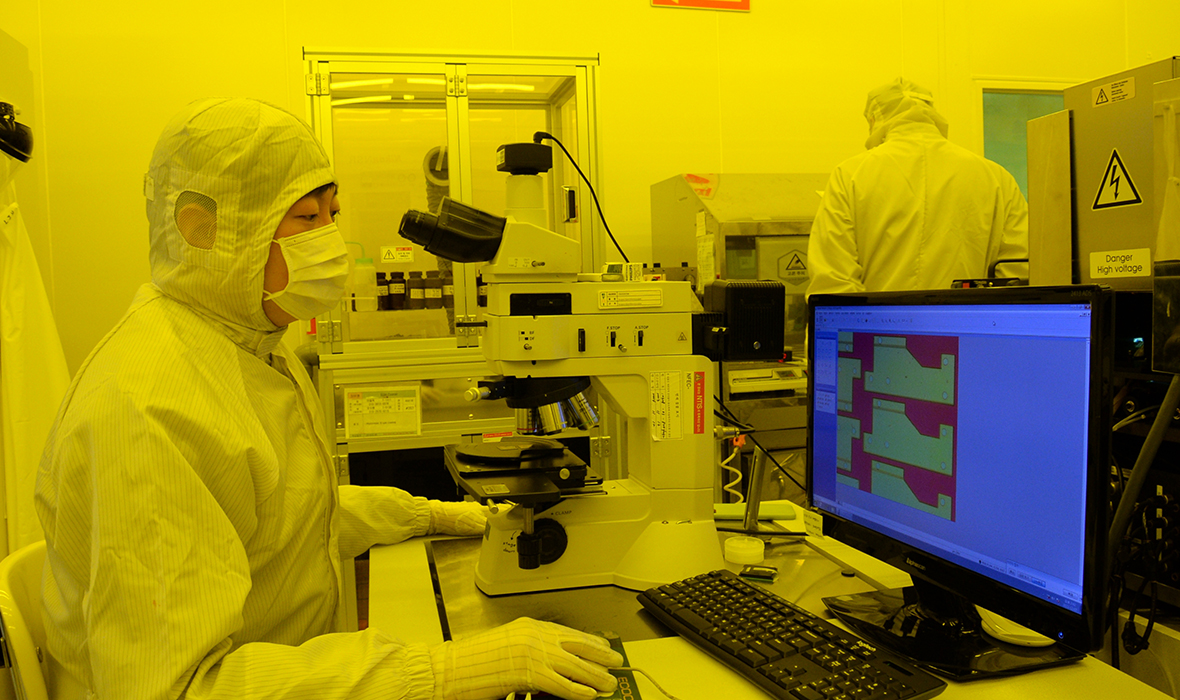

In addition to that, the research team evaluated this as a case of successful strategy that showed how the pilot study of ETRI was transferred to industry and realized as a commercial product even though it was extremely sensitive foundry mission. The In-Al-Ga-As(Indium-Aluminum-Gallium-Arsenic) compound composition, which was advantageous in terms of performance of laser diode such as output intensity and modulation speed at high temperature, but had poor reliability, was replaced with In-Ga-As-P(Indium-Gallium-Arsenic-Phosphorus) composition. In the company’s mass production process in the future, the strategy that was changed in favor of considering rapid commercialization and securing early reliability was effective.

EML produced in the mass production process of ELDIS Co., Ltd. can transmit 25 Gbps at high temperatures of 55 ℃ as well as at room temperature.

In addition, it has also secured 100 Gbps modulation speed that can be applied to the data center network and it is on a par with global competition products.

ELDIS Co., Ltd. aims to increase the mass production yield of 25 Gbps products first, supply them to domestic and overseas 5G markets, and to release 100 Gbps products in the first half of next year.

In the future, ETRI and ELDIS Co., Ltd. plan to continue to cooperate in strengthening product competitiveness through performance improvement and diversification of EML. Efforts will also be made to optimize performance through application of optical modules and evaluation technologies such as characteristics and reliability after fabrication process.

Lee Jong-jin, director of the optical packaging research department at ETRI, said, “I think it is very meaningful that the research team’s pilot research successfully led to commercialized product. In this way, we believe that we effectively saved the time and cost and we will continue to cooperate to support it to become the world’s best product.”

Han Young-tak, head of technology transfer at ETRI, also said, “In the case of compound optical semiconductors that are very sensitive to process variables, stable foundry operation is the key. We will try to maintain the foundry in best condition to make the researchers produce the best results in the world.” he said.

Cho Ho-seong, CEO of ELDIS Co., Ltd., said, “Korean government’s policy to promote the domestic materials, component, and equipment industry has been bearing fruit little by little. With the success of localization of high-value-added light sources such as EML, we need continuous support from government-funded research institutes and the government to reinforce the domestic supply chain and catch up with global market leader.”

This was achieved through the Ministry of Science and ICT’s ‘Development of low power On-Board integrated 400 Gbps Trasmitting/Receiving Optical Engine for Hyper-scale Data Center’ project and ‘Development of 800 Gbps optical transceiver for intra-datacenter networks’ task.

Jong-jin Lee, Director

Optical Packaging Research Secton

(+82-62-970-6622, jongjin@etri.re.kr)