ICT Trend

Vol.72

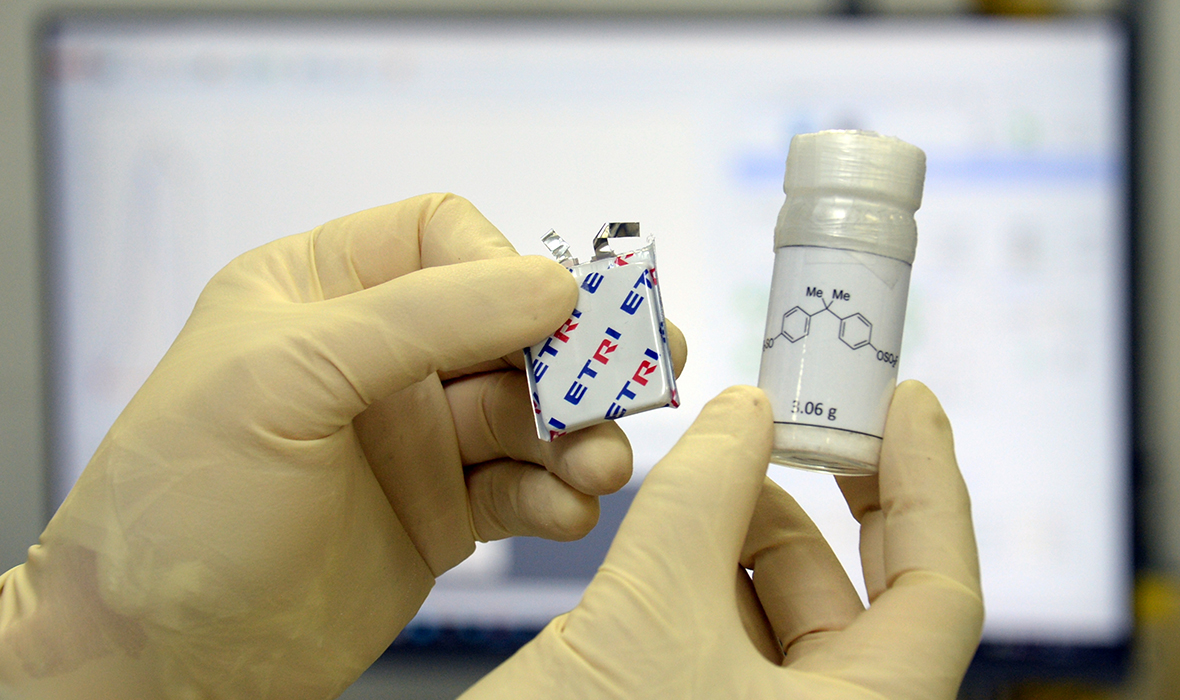

ETRI develops the world’s first fluorosulfated-based flame retardant additive

- Realization of highly safe lithium-ion battery, overcoming electric vehicle fire risk

- 2.3 times more flame retardant and 160 % battery performance than conventional phosphorous flame retardant additive,

In lithium-ion batteries commonly used in electric vehicles, incombustible additives are added to the electrolyte in preparation for the possibility of ignition. ETRI researchers succeeded in developing a fluorosulfate-based flame retardant additive for the first time in the world. This is expected to be of great help in realizing high-safety lithium-ion batteries and overcoming the fire risk of electric vehicles.

The Electronics and Telecommunications Research Institute(ETRI) announced that it has developed a fluorosulfated-based flame retardant additive with significantly improved flame retardant properties, electrochemical stability, and cell performance compared to triphenyl phosphate(TPP), a phosphorous flame retardant widely known as a conventional flame retardant(not yet commercialized).

The lithium-ion battery is composed of four components: a cathode material, an anode material, an electrolyte, and a separator. Lithium ions from the cathode move to the anode to be charged with input energy and then move from the anode to the cathode to release energy. The electrolyte is a medium that helps the lithium ions in the battery to move smoothly, and the separator serves to pass only the lithium ions and prevents contact between the cathode and anode. This is because a fire may occur due to a strong chemical reaction when the cathode and anode come into direct contact.

Electrolyte additive is a substance that is added in a small amount to electrolytes and are key substances that improve the electrochemical stability and performance of secondary batteries. Existing conventioanl phosphorous flame retardant additives had flame retardant properties, but a large amount was required. In addition, interfacial resistance, a chemical reaction that occurs at the interface where two materials with different properties come into contact, also occured between the electrode and the electrolyte. When this resistance increases, problems such as deterioration in performance of the battery and reduction in lifespan occur due to a decrease in ionic conductivity. A wider uses of additives had many limitations in their practical fields.

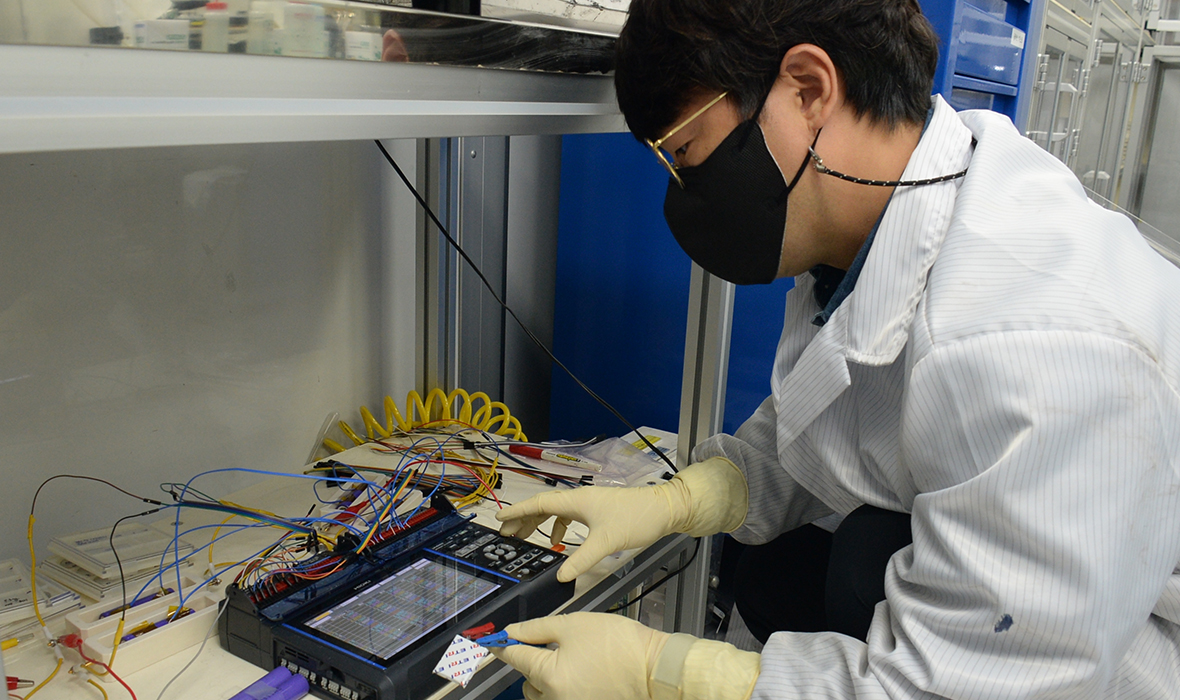

Accordingly, the ETRI research team analyzed more than 10 types of commercially available phosphorous flame retardants through electrochemical experiments, synthesized a fluorosulfated-based flame retardant additive for the first time, and improved the shortcomings of convetional phosphorous flame retardants. The research team implemented the developed flame retardant additive to the cell with a lithium nickel, manganese, and cobalt transition metal oxide cathode(Nickel content > 90 %) and a lithium metal anode. Through these tests, the performance of fluorosulfated-based additive was verified with improved battery performance at the same time as improving flame retardant properties.

As a result, it was confirmed that the flame retardant properties were improved by 2.3 times and the performance of the battery by 160 %, compared to the electrolyte to which the conventional flame retardant additive was applied. The research team explained that when the fluorosulfated-based flame retardant was applied, the interfacial reaction between the electrode and the electrolyte was minimized, resulting in a significant decrease in interfacial resistance.

In addition, this fluorosulfated-based flame retardant additive has the advantage of being easy to commercialize as it can be used even with a small amount of additive developed without an additional process change in the existing lithium-ion battery production process.

The research team identified the characteristics of fluorosulfated-based additives through various electrochemical experiments and verified why these operation mechanism is possible.

This achievement was published in the latest issue of ‘Journal of Materials Chemistry A (IF=14.511, within 10 % of JCR, as of 2022)’ published by the Royal Society of Chemistry, a world-class academic journal in the field of materials and chemistry, proving its excellence.

Jimin Oh, a senior researcher at the Intelligent Sensor Lab, said, “We wanted to overcome the limitations of exiting flame retardant additives and realize highly safe lithium-ion batteries through these research on new type of flame retardant additive. In the future, we will make efforts to contribute to the commercialization of fluorosulfated-based flame retardant additive to the practical electric vehicle cells.”

The research team at the ETRI has devised a plan to carry out further studies on the application of a flame-retardant additive material in lithium metal oxide anodes and lithium metal cathodes in black oxide electrodes and silicon electrode cathodes.

This study was supported by the “Development of High-Performance Multi-functional Electrolyte and Additive Characteristics Improvement Technology for Lithium-ion Batteries” project of the Ministry of Science and ICT and the National Core Material Research Center of the Korea Research Foundation. The achievement was made possible through the collaboration of ETRI, the Ulsan National Institute of Science and Technology, and Enchem Co., Ltd., who served as the main participants.

Oh Ji min, Senior Researcher

Smart Materials Research Section

(+82-42-860-0783, ojmhiin@etri.re.kr)