VOL. 65 June 2021

ETRI Develops

Radiation-Resistant Sensors

- Temperature and pressure can be measured even when exposed to gamma radiation of 20 kGy

- Applicable to extreme environments such as nuclear facilities, without the need of the heavy lead shielding system

The domestic research team developed the flexible composite-based sensor that is resistant to high energy radiation. This material is expected to be used effectively for producing a radiation-resistant sensor that can be used to measure the pressure and temperature inside the nuclear facility..

The Electronics & Telecommunications Research Institute (ETRI) announced that the composite material was developed by combining Graphene1), MXene2), and Ecoflex3) and applied in producing the radiation-resistant pressure-temperature sensor.

The nuclear power plant uses elements such as radium, uranium, thorium, polonium, etc. to produce electric power, and gamma radiation is emitted in the process of handling these elements. The gamma radiation has very high penetrating power to cause failure or malfunction of electronic devices, and it can cause great harm to biological tissues in case the human body is exposed to it.

1) Carbon allotrope in very thin 2D plane structure with one layer 0.3 nm (1m of 1 billion) thick. Has high physical and chemical stability and high thermal conductivity.

2) The 2D substance in thin plate shape composed of titanium and carbon atom, etc., has thickness of only 1㎚ or less and shows outstanding electrical conductivity.

3) One type of silicone resin. Has the property of being flexible, smooth, and elastic.

In the existing nuclear energy sectors, the sensors are mostly developed with semiconductor materials, with lead shielding added to prevent the penetration of radiation. Also, most of the protective clothing worn by personnel with access to the relevant facilities is produced with lead, but there are disadvantages of increase in weight and volume of the equipment.

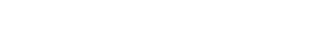

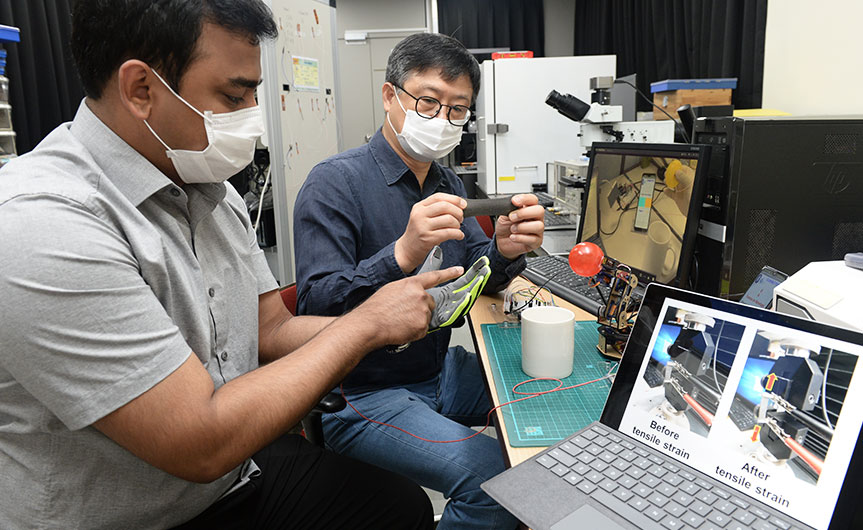

Accordingly, ETRI developed a composite sensor that can measure both pressure and temperature without any physical and chemical changes even when the sensor is exposed to radiation with high energy. The sensor developed by the research team had its performance verified through the Korea Atomic Energy Research Institute (KAERI) and Advanced Radiation Technology Institute (ARTI) in Jeong-eup; thus successfully proving its excellence.

The material was tested in the laboratory with a gamma radiation intensity that is critical to the human body. When gamma ray4) of 20kGy5) was irradiated from cobalt-606) for 24 hours, the research team verified that there were no changes or abnormalities in the material.

4) As the highest energy area in the electromagnetic spectrum, it is produced by the nuclear process of radioactive and positron annihilation, etc.

5) Gray (Gy). Unit of absorbed dose showing the degree of radiation energy from the object being absorbed to the medium.

6) Created by colliding neutrons artificially with the cobalt-59 atom, with high level of gamma ray and beta rays emitted.

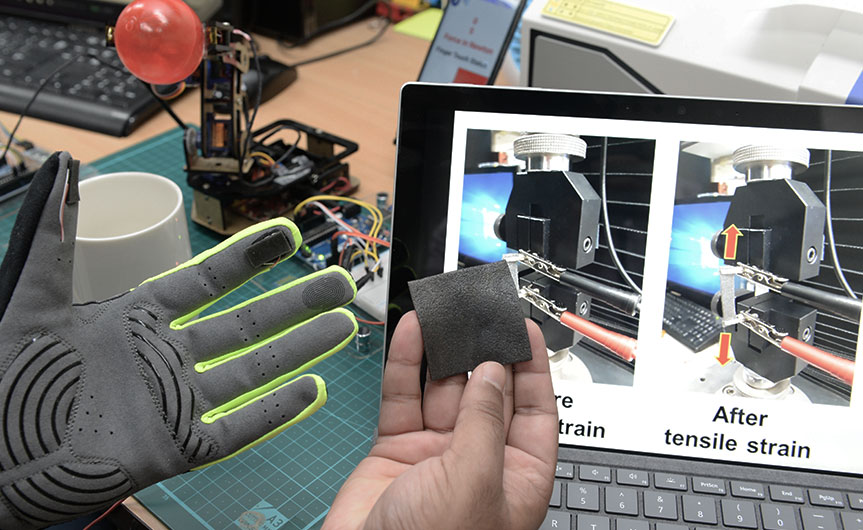

The developed sensor is flexible and lightweight, which can be produced with large area and various forms. Thanks to these advantages, we expect to apply this material without the heavy lead shielding in the areas exposed to radiation at the nuclear facilities and hospitals.

The sensor can also be used for detecting objects, and the research team verified through the test that the sensor has high sensitivity to applied pressure, and can respond to the difference in grasping pressure depending on the weight, hardness, shape, etc. The sensor can also detect thetemperature of different objects. . Consequently, the sensor can be applied to the prosthetic arm as well as to the robots deployed to extreme locations with severe radiation exposure to perform the advanced tasks instead of human.

Furthermore, this material also shows excellent high-frequency electromagnetic wave shielding effect to be useful for application to electronic devices for 5G communication, radar system in the autonomous vehicle and in the aerospace industry, etc. We also expect this material to be used effectively in household appliances, electronic equipment for industries such as medical and national defense industries, and electronic parts used in extreme environmental conditions and in smart electronic devices.

The research team revealed that the sensor was developed through technical know-how related to the 2D composite material7) accumulated for a long time. Especially, the research team attributes this successful result to the technology of manufacturing and combining appropriate materials.

“We hope to use the outstanding performance of this technology to support safe and convenient work in an environment exposed to a high amount of radiation and shielding the electromagnetic waves or enable the easy operation of electronic devices,” said Dr. Choi Choon-Gi from the ETRI Nano Electron Source Research Team.

This research was conducted through the support for the Nuclear R&D Project by the Ministry of Trade, Industry & Energy, and patent registration for the technology developed by the research team is pending in Korea and US. This technology has high degree of completion to enable technical transfer immediately to material and sensor manufacturers, and the research team is looking forward to product commercialization within 2 years.

7) Composite material produced based on 2D substances several nanometers thick.