ETRI’s Latest Broadcasting Technology Received Rave Review at NAB 2016

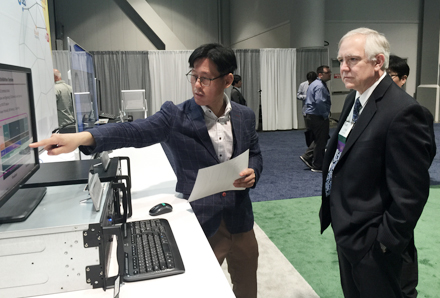

On April 18, ETRI participated in the NAB (National Association of Broadcasters) Show 2016, the world’s largest exhibition for broadcasting equipment, held in Las Vegas, United States. Demonstrating its next-generation broadcasting technology at the event, the institution paved the way for allowing Korean researchers to drive a new broadcasting market in the future. This year’s NAB Show became the first venue where ETRI showcased its four technologies related to UHD television service, and these new media technologies for broadcasting and communications are receiving increasing attention from the global market.

During the show, distinguished visitors to ETRI’s exhibition booth included President Mark Richer of the ATSC (Advanced Television Systems Committee); NAB’s Senior Vice President Lynn Claudy; Rich Chernock, ATSC’s TG3 Chair; and Wenjun Zhang, Chief Scientist at NERC-DTV (National Engineering Research Center of Digital Television). The participants unanimously offered a favorable reaction to ETRI’s latest broadcasting technology. To participate in the show, ETRI had helped commercialization of technology through joint research with small and medium businesses, technology transfer and also supported equipment standard compliance tests and inter-equipment conformance tests.

“By taking advantage of the world’s largest broadcasting exhibition, we will continue introducing Korea’s latest broadcasting and communications media technology and securing its reliability,” explains Dr. Chieteuk Ahn, Senior Vice President of ETRI. “We will also use the event as an opportunity to help Korean broadcasting equipment developers enter overseas markets and to vitalize UHD television services both in Korea and around the world.

In February 2016, ETRI became the world’s first agency to successfully verify the ATSC 3.0 transmission and reception technology, the next-generation terrestrial standard, at a high-frequency VHF channel in the test conducted in the United States. In 2015, it also completed the world’s first field test for LDM (layered division multiplexing) technology to simultaneously transmit and receive UHD broadcasting and mobile HD broadcasting via a single channel.

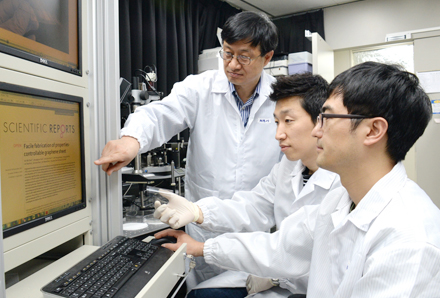

Large-Area Graphene Synthesis Technology Developed for Flexible Displays

A team of Korean researchers at ETRI developed large-area graphene synthesis technology for transparent electrodes applicable to flexible displays. On April 27, ETRI announced that the team led by Dr. Choon-Gi Choi of the Materials and Components Creative Research Section had successfully developed technology to simultaneously control the properties of sheet resistance and transmittance and synthesize 4-inch-large high-quality graphene.

Graphene is a thin film-shaped nanomaterial where carbon atoms are aligned into a hexagonal pattern. It is extremely thin, approximately 0.3nm (nm is one-billionth meter) or one-millionth of the thickness of a human hair, and owing to its outstanding conductivity, transmittance, and flexibility, graphene is a highly promising future electronic material.

Although ITO (indium tin oxide) is currently in wide use for transparent electrodes, it presents some shortcomings such as breakage when used for flexible displays. In this regard, graphene, metal mesh, and nanowire have emerged as potential alternatives.

Whereas graphene presents excellent transmittance, its high sheet resistance results in inaccurate touch performance on displays and requires a high level of voltage. To address this issue, the team of researchers controlled the sheet resistance and the transmittance by using a copper-nickel alloy catalyst instead of copper, a catalyst that has long been employed for graphene synthesis, and consequently succeeded in synthesizing large-size graphene.

The researchers explain that both single-layered graphene and multi-layered graphene were synthesized with the controlled ratio of copper-nickel alloy catalyst. It thus presents an advantage in terms of process efficiency and yield compared to the method of repetitively piling up single-layered graphene to form multi-layered graphene.