Don’t Wear a Wearable Device—Attach It!

An Era of Attachable Wearable Devices

Personal computers and telephones had once been used only in the home, but they have been developed into portable smartphones. In addition to such mobility, information technology has innovated devices with the advent of smart wearable devices. The term ‘wearable device’ refers to glasses, watches, or band-type devices that can be used through wireless connection with smartphones or tablet PCs.

Presently, the global market for wearable devices continues to grow and will achieve sales of USD 19 billion by 2018. A number of companies are constantly developing and releasing diverse wearable devices. Some of the latest products include devices to be worn on the wrist, face, or fingers.

Researchers around the world have strived to develop wearable devices to attach to the surface of the human body, but the thin patches used for human contact often result in drastically reduced mechanical stability. Since the patches are easily ripped or rolled, it is difficult to remove or relocate the patches and they are therefore used only once.

To address these issues, ETRI has successfully developed a patch structure that can be attached to bumpy micrometer-sized cells based on outstanding mechanical stability and accessibility. This achievement is expected to facilitate the transmission of signals and materials between the patch and human skin, substantially improving the reliability of bio-diagnosis and the performance of drug patches in the future.

Attach or Detach Your Wearable Patches

To address the challenges faced by existing wearable devices to attach upon the human body surface, the ETRI researchers focused on the fact that a liquid can wet a solid object for more precise contact. They presumed that such ‘wetting’ could happen between solid objects and further studied the phenomenon.

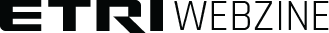

The researchers used a polymer material called PUA (polyurethane acrylate) to simultaneously ensure mechanical stability and excellent wetting. Using imprint technology, they produced a thin film where structures of different sizes coexist.

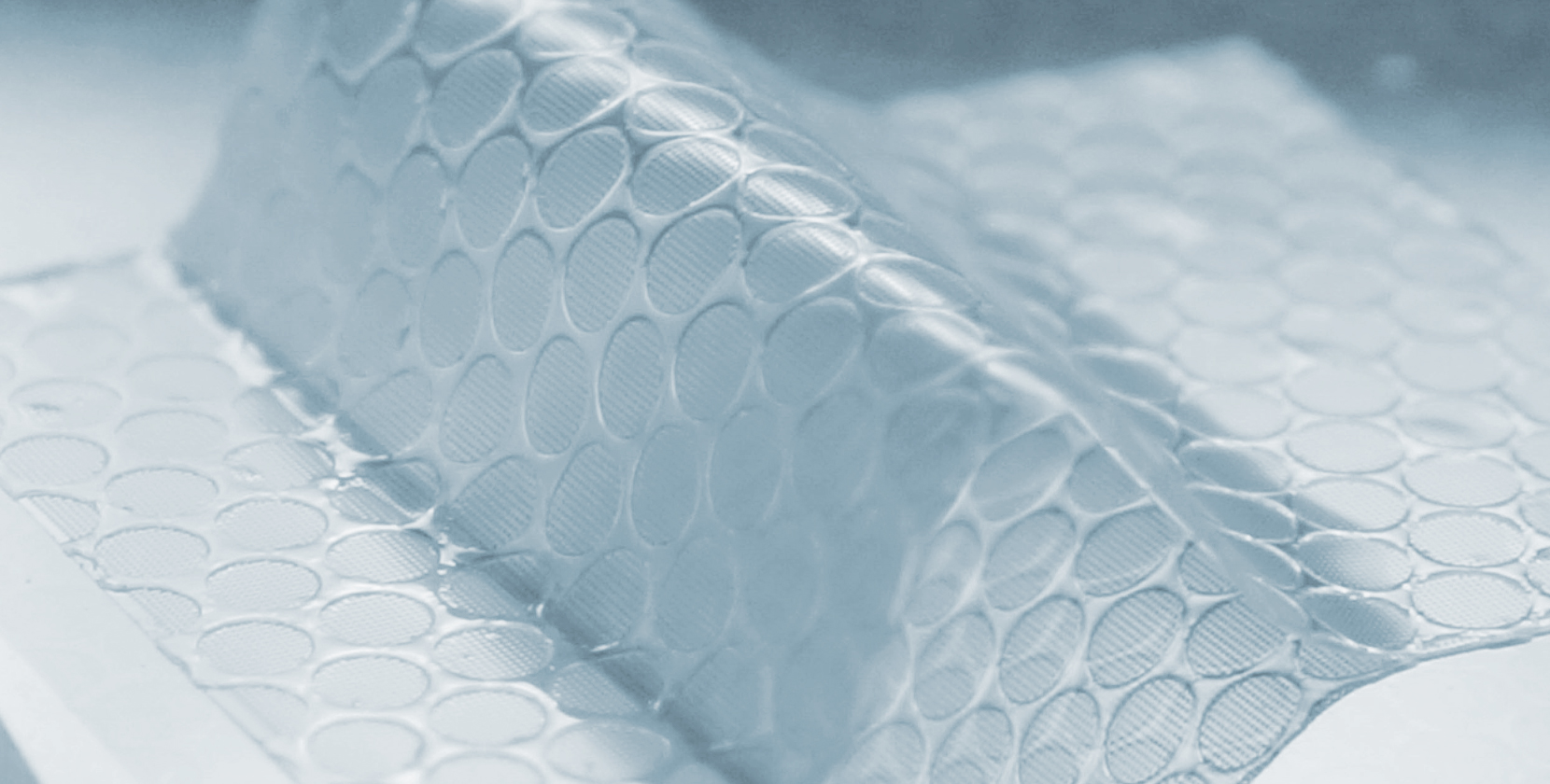

By hierarchically positioning thin nano-thin films with excellent wetting ability and micro-thin films that have poorer wetting performance but can support thin films, the research team created a thin film with a three-layer hierarchical structure from 500 micrometers to 800 nanometers. Such a multi-scale structure led to a design principle with outstanding contact performance and mechanical stability. Although the existing patches are mostly disposable, the patches developed by the researchers at ETRI can be easily attached and detached, are reusable, and can provide very close contact even onto coarse cells.

This achievement is significant in that it identified a general design principle going beyond specific materials or environments. Accordingly, the structure can be designed without difficulty even for patches to be attached to anything other than human skin and for materials other than the PUA, enabling customized designs. To prove the tailored design, ETRI produced a 1cm x 1cm patch that is 26 micrometers thick, which could be attached well onto the palm. Although the naked eye cannot observe this nano-level contact, the patch attached onto the palm as if it were wet with water.

Attachable Everywhere in Addition to Human Skin

The researchers also proved that the new patch can contact very closely on surfaces with cell-level curvature, such as uneven leaves, pig skin, and human hair. They also demonstrated that the patch can be attached and detached repetitively based on its high mechanical stability.

Fundamentally, the patch was made with imprint and roll-to-roll processes, enabling the patch to be made in larger sizes and with non-PUA materials. When a patch that attaches upon human skin well is developed, high-quality biometric information will be obtained and facilitate popularization of wearable devices.

The development of these patch structures was published in Advanced Materials, a world-renowned journal, and was selected as the frontispiece cover. The development was supported as part of the National Research Council of Science and Technology’s convergent research project and ETRI-KISTI collaborative research project. It was also a collaborative research outcome of ETRI as well as KIST (Korea Institute of Science and Technology), and the University of Pennsylvania and the University of Chicago in the United States. The principal author is Dr. Junsoo Kim, a researcher in ETRI’s ICT Materials Research Group; Dr. Seung Eon Moon also participated in the research. The corresponding author is Dr. Hyesung Cho, who is working as a post-doc researcher at the University of Pennsylvania.